Have you ever wondered how businesses seamlessly convert investments into cash, ensuring smooth financial operations? In this guide, we’ll unravel the intricacies of the operating cycle, shedding light on its crucial role in financial management. You’ll explore the components, calculation methods, practical strategies, key performance indicators, and the tools needed to master the art of optimizing your operating cycle for enhanced efficiency and profitability. Dive in and unlock the secrets to a thriving financial cycle.

What is the Operating Cycle?

The operating cycle, often referred to as the cash conversion cycle, is a fundamental concept in financial management. It represents the time it takes for a business to convert its investments in inventory and other resources into cash through sales and accounts receivable collection. This cycle is a crucial measure of a company’s financial efficiency and liquidity. To put it simply, the operating cycle measures how quickly a company can turn its resources into cash flow.

Importance of Operating Cycle

Understanding the significance of the operating cycle is vital for businesses of all sizes and industries. Here’s why it’s essential:

- Cash Flow Management: The operating cycle directly impacts a company’s cash flow. A shorter cycle means quicker access to cash, which is crucial for meeting financial obligations, investing in growth, and weathering economic uncertainties.

- Working Capital Efficiency: Efficient management of the operating cycle helps minimize the amount of capital tied up in day-to-day operations. This reduces the need for external financing and lowers the associated costs.

- Inventory Control: Businesses with a firm grasp of their operating cycle can manage their inventory more effectively. This leads to lower carrying costs, reduced risk of inventory obsolescence, and improved profitability.

- Customer and Supplier Relationships: A well-managed operating cycle enhances relationships with customers and suppliers. Prompt collections from customers improve customer satisfaction, while optimized accounts payable practices can extend payment terms and strengthen vendor relationships.

Purpose of Understanding the Operating Cycle

Understanding the operating cycle serves several critical purposes in financial management:

- Financial Health Assessment: It provides a snapshot of a company’s financial health. A lengthy operating cycle may signal inefficiencies that need addressing, while a short one can indicate good financial health.

- Decision-Making: Business leaders can use the operating cycle to make informed decisions about inventory levels, credit policies, and supplier relationships. It guides strategic choices that impact cash flow and profitability.

- Performance Benchmarking: Comparing your operating cycle to industry benchmarks or competitors’ cycles can highlight areas for improvement and competitive advantages.

- Cash Flow Forecasting: The operating cycle is a valuable tool for cash flow forecasting. Understanding how long it takes for investments to turn into cash helps businesses plan for short-term liquidity needs.

- Investor and Lender Confidence: Investors and lenders often assess a company’s operating cycle to gauge its financial stability and management’s ability to generate cash. A well-managed cycle can instill confidence and attract investment or favorable lending terms.

By comprehending the definition, recognizing the importance, and understanding the purposes of the operating cycle, businesses can make informed financial decisions and work towards optimizing this critical aspect of their operations.

Conclusion

Understanding and managing your operating cycle is fundamental to your business’s financial health. By efficiently handling inventory, accounts receivable, and accounts payable, you can shorten your cycle, improve cash flow, and boost profitability. Monitoring key performance indicators and utilizing the right tools further enhances your ability to succeed in this critical aspect of financial management.

Remember, your operating cycle is not static; it requires continuous attention and adaptation to changing market conditions. By implementing the strategies outlined in this guide and staying vigilant, you can achieve a more efficient operating cycle, setting your business on the path to financial success.

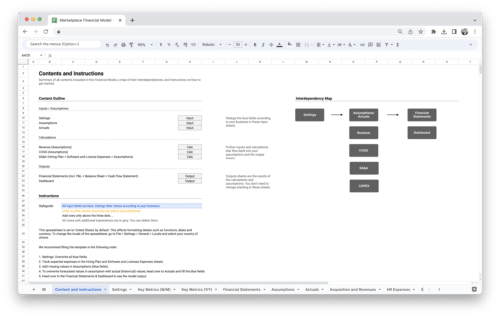

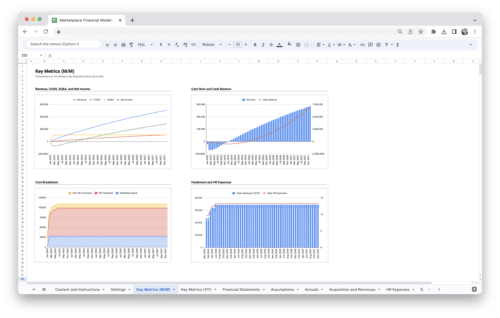

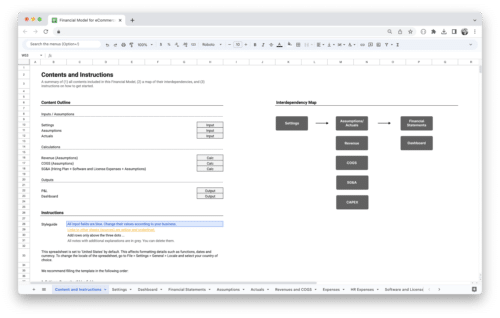

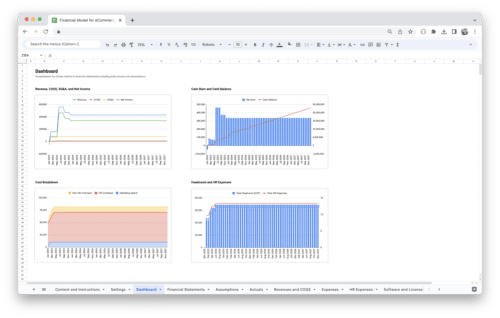

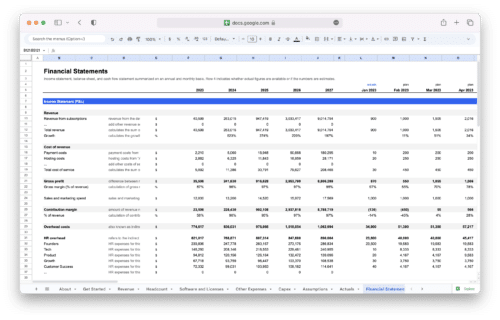

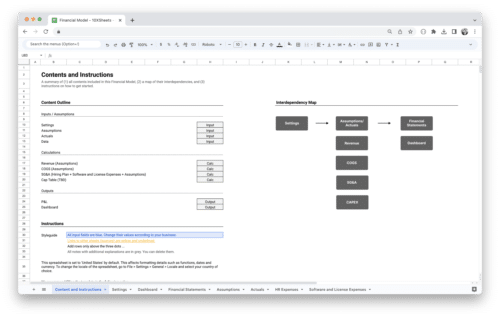

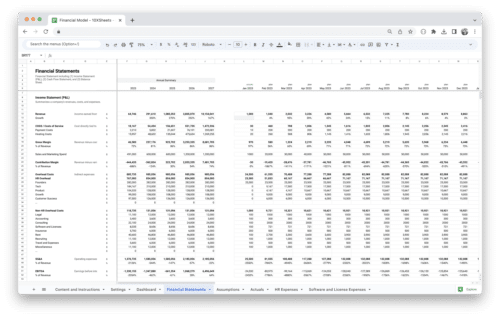

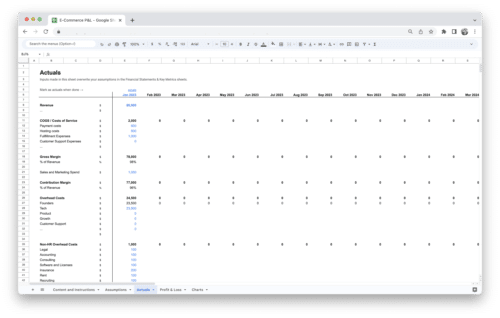

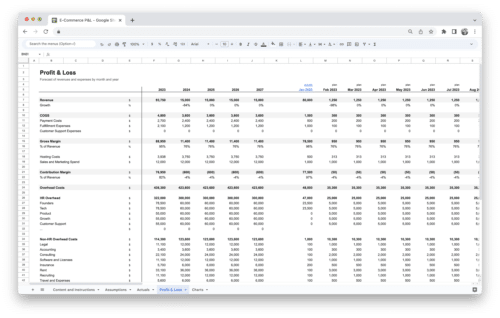

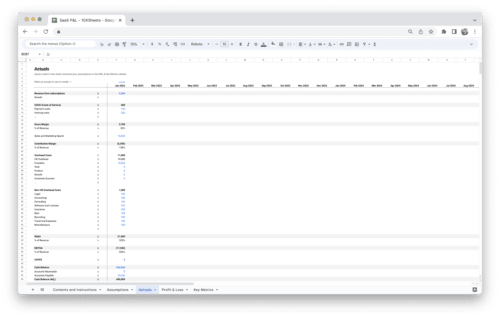

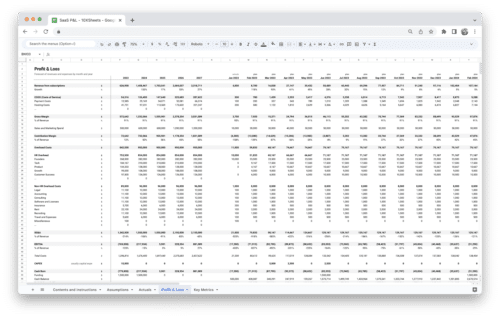

Get Started With a Prebuilt Template!

Looking to streamline your business financial modeling process with a prebuilt customizable template? Say goodbye to the hassle of building a financial model from scratch and get started right away with one of our premium templates.

- Save time with no need to create a financial model from scratch.

- Reduce errors with prebuilt formulas and calculations.

- Customize to your needs by adding/deleting sections and adjusting formulas.

- Automatically calculate key metrics for valuable insights.

- Make informed decisions about your strategy and goals with a clear picture of your business performance and financial health.