Have you ever wondered how businesses keep track of all the products they buy, sell, and store? Well, that’s where inventory management comes in. Inventory management is like the backbone of any business operation, ensuring that the right products are available at the right time and in the right quantity. It’s all about keeping tabs on what’s in stock, what’s running low, and what needs to be reordered. From small mom-and-pop stores to large multinational corporations, effective inventory management is essential for keeping operations running smoothly, minimizing costs, and satisfying customers.

In this guide, we’ll dive deep into the world of inventory management, exploring everything from its basic principles to advanced techniques and software solutions. Whether you’re a business owner looking to streamline your inventory processes or simply curious about how it all works, this guide has got you covered.

What is Inventory?

Inventory management is the process of overseeing and controlling the flow of goods into and out of a company’s inventory. It involves monitoring inventory levels, tracking inventory movements, and ensuring the availability of goods for production or sale.

Inventory management encompasses a range of activities, including:

- Inventory Tracking: Monitoring the quantity and location of inventory items in real-time.

- Order Management: Processing orders, managing purchase orders, and tracking order fulfillment.

- Stock Replenishment: Reordering inventory items to maintain optimal stock levels.

- Inventory Valuation: Assigning a monetary value to inventory items for accounting and financial reporting purposes.

- Inventory Optimization: Balancing inventory levels to minimize costs while ensuring product availability.

Effective inventory management is essential for businesses of all sizes and industries to optimize resources, minimize costs, and maximize profitability.

Importance of Inventory

Inventory plays a critical role in the success of a business. Here are some key reasons why inventory management is important:

- Customer Satisfaction: Maintaining adequate inventory levels ensures that products are available when customers need them, leading to improved customer satisfaction and loyalty.

- Operational Efficiency: Effective inventory management streamlines operations, reduces stockouts and excess inventory, and optimizes resource utilization, leading to improved efficiency and productivity.

- Cost Control: Proper inventory management helps minimize inventory holding costs, reduce obsolescence, and prevent stockouts, leading to cost savings and improved profitability.

- Revenue Generation: By ensuring product availability and timely order fulfillment, inventory management contributes to increased sales and revenue generation.

- Competitive Advantage: Efficient inventory management enables businesses to respond quickly to changes in demand, adapt to market trends, and gain a competitive edge over competitors.

Benefits of Effective Inventory Management

Effective inventory management offers numerous benefits for businesses:

- Cost Savings: Optimizing inventory levels, reducing carrying costs, and minimizing stockouts can result in significant cost savings for businesses.

- Improved Cash Flow: Efficient inventory management frees up working capital by minimizing tied-up inventory and reducing the need for excessive borrowing or financing.

- Enhanced Customer Service: Maintaining optimal inventory levels ensures product availability, reduces lead times, and improves order fulfillment, leading to better customer service and satisfaction.

- Operational Efficiency: Streamlining inventory processes, automating tasks, and leveraging technology can improve operational efficiency and productivity.

- Better Decision-Making: Access to real-time inventory data, analytics, and insights enables businesses to make informed decisions and optimize inventory strategies.

- Supply Chain Optimization: Effective inventory management contributes to a more agile and responsive supply chain, enabling businesses to adapt to changes in demand, mitigate supply chain risks, and improve overall supply chain performance.

By implementing effective inventory management practices, businesses can achieve cost savings, improve customer satisfaction, and gain a competitive advantage in the market.

Types of Inventory

Understanding the various types of inventory is fundamental to effective inventory management. Each type serves a specific purpose within the supply chain and requires distinct management strategies to optimize operations and minimize costs.

Raw Materials

Raw materials are the foundation of production processes, encompassing the basic components and resources required to manufacture finished goods. These materials can vary significantly depending on the industry and production methods. For example, in the textile industry, raw materials may include cotton, polyester, and dyes, while in the automotive industry, they may consist of steel, rubber, and plastic components.

Managing raw materials involves several key considerations:

- Sourcing: Procuring raw materials from reliable suppliers while considering factors such as quality, cost, and lead times.

- Inventory Levels: Balancing inventory levels to ensure an adequate supply for production without excessive carrying costs or the risk of stockouts.

- Quality Control: Monitoring the quality of raw materials to maintain product standards and prevent defects or production delays.

- Storage and Handling: Properly storing and handling raw materials to prevent damage, spoilage, or theft.

Work-in-Progress (WIP)

Work-in-progress inventory represents partially completed goods that are in various stages of the production process. It includes materials, components, and sub-assemblies that have undergone some processing but are not yet finished products ready for sale.

Managing WIP inventory requires close coordination between production, procurement, and scheduling departments to:

- Optimize Workflow: Streamline production processes to minimize bottlenecks and maximize efficiency.

- Monitor Production Metrics: Track key performance indicators such as cycle time, throughput, and work-in-progress inventory levels to identify areas for improvement.

- Just-in-Time Production: Implement just-in-time manufacturing principles to reduce WIP inventory levels and minimize waste.

- Quality Assurance: Conduct regular inspections and quality checks to ensure that WIP items meet specifications and standards.

Finished Goods

Finished goods are products that have completed the production process and are ready for sale to customers. Managing finished goods inventory involves balancing supply and demand to ensure adequate stock levels without excess inventory or stockouts.

Key considerations for managing finished goods inventory include:

- Demand Forecasting: Using historical sales data, market trends, and other factors to forecast future demand and plan production accordingly.

- Inventory Turnover: Monitoring inventory turnover rates to ensure that products are sold within a reasonable timeframe and minimize carrying costs.

- Seasonal Variations: Anticipating seasonal fluctuations in demand and adjusting inventory levels accordingly to avoid overstocking or stockouts.

- Product Lifecycle Management: Managing inventory levels throughout the product lifecycle, including introduction, growth, maturity, and decline stages.

Maintenance, Repair, and Operations (MRO) Inventory

MRO inventory consists of materials and supplies used for maintenance, repair, and operations activities to support ongoing operations. This category includes items such as spare parts, consumables, tools, and equipment needed to maintain facilities and machinery.

Managing MRO inventory involves:

- Predictive Maintenance: Implementing predictive maintenance strategies to anticipate equipment failures and stock necessary spare parts in advance.

- Supplier Management: Establishing relationships with reliable suppliers to ensure timely delivery of MRO items and minimize downtime.

- Inventory Optimization: Using inventory optimization techniques such as ABC analysis to prioritize MRO items based on criticality and usage frequency.

- Asset Tracking: Implementing asset tracking systems to monitor MRO inventory levels, locations, and usage patterns for better inventory control.

Goods in Transit

Goods in transit refer to inventory items that are in the process of being transported from one location to another, such as from suppliers to warehouses or from warehouses to customers. Managing goods in transit effectively is crucial for maintaining supply chain efficiency and meeting customer expectations.

Key considerations for managing goods in transit include:

- Logistics Management: Optimizing transportation routes, modes, and carriers to minimize transit times and costs.

- Visibility: Implementing tracking and visibility solutions to monitor the status and location of goods in transit in real-time.

- Risk Management: Identifying and mitigating risks associated with transportation, such as delays, damages, or theft.

- Collaboration: Collaborating with suppliers, logistics partners, and customers to coordinate shipments and ensure on-time delivery.

Safety Stock

Safety stock, also known as buffer stock, is extra inventory held to protect against uncertainties in demand, supply chain disruptions, or lead time variability. It serves as a cushion to prevent stockouts and ensure continuity of operations.

Managing safety stock involves:

- Demand Variability: Analyzing demand patterns and fluctuations to determine appropriate safety stock levels based on factors such as seasonality, market trends, and promotional activities.

- Lead Time Variability: Accounting for variability in lead times for procurement, production, and transportation when calculating safety stock levels.

- Service Level Targets: Balancing the trade-off between service level targets and inventory carrying costs to achieve optimal inventory performance.

- Dynamic Adjustments: Continuously reviewing and adjusting safety stock levels based on changes in demand, lead times, and other factors affecting inventory availability.

Inventory Management Techniques

Implementing effective inventory management techniques is essential for optimizing inventory levels, reducing costs, and improving operational efficiency. We’ll explore various techniques commonly used by businesses to manage their inventory effectively.

ABC Analysis

ABC analysis is a method used to categorize inventory items based on their importance and value to the business. It classifies items into three categories: A, B, and C, representing high, medium, and low-value items, respectively.

- Category A: Includes high-value items that contribute significantly to revenue or have high carrying costs. These items require careful monitoring and tighter inventory control.

- Category B: Consists of medium-value items that have moderate importance to the business. They require regular monitoring and management to ensure optimal inventory levels.

- Category C: Comprises low-value items with minimal impact on revenue or carrying costs. These items can be managed with less scrutiny and lower inventory levels.

ABC analysis helps businesses prioritize inventory management efforts, allocate resources effectively, and focus on the most critical items to improve overall inventory performance.

Just-In-Time (JIT) Inventory Management

Just-in-Time (JIT) inventory management is a strategy aimed at minimizing inventory holding costs by synchronizing production with customer demand. In JIT systems, inventory is ordered or produced only when needed, eliminating excess inventory and reducing waste.

Key principles of JIT inventory management include:

- Demand-Driven Production: Aligning production schedules with customer demand to minimize inventory buildup and maximize responsiveness to market changes.

- Lean Manufacturing: Implementing lean manufacturing principles such as waste reduction, continuous improvement, and pull-based production to streamline operations and optimize resource utilization.

- Supplier Collaboration: Building strong relationships with suppliers to ensure timely delivery of materials and components, reducing lead times and inventory holding costs.

- Quality Control: Emphasizing quality at every stage of the production process to minimize defects, rework, and waste.

JIT inventory management is widely used in industries such as automotive, electronics, and fast-moving consumer goods (FMCG) to achieve cost savings, improve efficiency, and enhance competitiveness.

Economic Order Quantity (EOQ)

Economic Order Quantity (EOQ) is a formula used to calculate the optimal order quantity that minimizes total inventory costs, including ordering costs and holding costs. The EOQ formula is based on the trade-off between the costs of holding inventory and the costs of ordering inventory.

The EOQ formula is expressed as:

EOQ = √((2DS) / H)

Where:

- D represents the annual demand for the item.

- S represents the ordering cost per order.

- H represents the holding cost per unit per year.

By calculating the EOQ, businesses can determine the most cost-effective order quantity that balances the costs of holding excess inventory with the costs of placing frequent orders.

Material Requirements Planning (MRP)

Material Requirements Planning (MRP) is a system for planning and managing inventory and production schedules based on demand forecasts. MRP software uses bill of materials (BOM) data, inventory levels, and production schedules to calculate the materials needed for production and generate procurement and production orders accordingly.

Key features of MRP systems include:

- Demand Forecasting: Using historical sales data, customer orders, and production schedules to forecast future demand for materials and components.

- Inventory Optimization: Determining optimal inventory levels to minimize stockouts while avoiding excess inventory and associated costs.

- Production Planning: Generating production schedules and work orders based on material availability, lead times, and capacity constraints.

- Supplier Collaboration: Communicating with suppliers to ensure timely delivery of materials and components to support production schedules.

MRP systems help businesses streamline procurement, production, and inventory management processes, improve resource allocation, and enhance overall operational efficiency.

Vendor-Managed Inventory (VMI)

Vendor-Managed Inventory (VMI) is a supply chain management practice in which the supplier takes responsibility for managing inventory levels at the customer’s location. In VMI arrangements, the supplier monitors inventory levels, replenishes stock as needed, and manages order fulfillment, freeing the customer from the burden of inventory management.

Key benefits of VMI include:

- Reduced Inventory Costs: By outsourcing inventory management to the supplier, customers can reduce carrying costs, obsolescence, and stockouts.

- Improved Supply Chain Visibility: Suppliers have real-time visibility into customer inventory levels, enabling proactive inventory management and demand forecasting.

- Enhanced Collaboration: VMI fosters closer collaboration between suppliers and customers, leading to better communication, trust, and alignment of goals.

- Increased Efficiency: With VMI, customers can focus on core competencies such as sales, marketing, and product development, while suppliers handle inventory replenishment and order fulfillment.

VMI is commonly used in industries such as retail, consumer goods, and automotive to streamline supply chain operations, reduce inventory costs, and improve service levels.

Consignment Inventory

Consignment inventory is a business arrangement in which the supplier retains ownership of the inventory until it is sold by the customer. In consignment agreements, the supplier delivers goods to the customer’s location but retains legal ownership and control over the inventory until it is sold to an end customer.

Key features of consignment inventory include:

- Risk Sharing: Suppliers retain ownership of inventory until it is sold, reducing the risk for customers and allowing them to free up capital for other investments.

- Flexible Payment Terms: Customers only pay for consigned inventory once it is sold, improving cash flow and reducing financial risk.

- Improved Inventory Turnover: Consignment inventory allows suppliers to rotate stock more frequently, reducing the risk of obsolescence and maximizing inventory turnover.

- Enhanced Supplier-Customer Relationships: Consignment agreements foster closer collaboration and trust between suppliers and customers, leading to better service levels and long-term partnerships.

Consignment inventory is commonly used in industries such as retail, automotive, and healthcare to reduce inventory carrying costs, improve cash flow, and strengthen supplier-customer relationships.

Dropshipping

Dropshipping is a retail fulfillment method where the retailer does not keep goods in stock but instead transfers customer orders and shipment details to the manufacturer, wholesaler, or another retailer, who then ships the goods directly to the customer. Dropshipping eliminates the need for inventory storage and reduces the risk of overstocking.

Key advantages of dropshipping include:

- Low Startup Costs: Dropshipping allows entrepreneurs to start an e-commerce business with minimal upfront investment since they don’t need to purchase inventory or warehouse space.

- Wide Product Selection: Dropshipping enables retailers to offer a wide range of products without the need for large inventories, allowing them to respond quickly to changing market trends and customer preferences.

- Flexibility: Dropshipping allows retailers to scale their businesses quickly and easily since they don’t need to manage inventory or fulfill orders themselves. This flexibility makes it ideal for businesses with fluctuating demand or seasonal sales patterns.

- Focus on Sales and Marketing: With dropshipping, retailers can focus on sales and marketing activities, such as building brand awareness, driving website traffic, and converting leads into customers, without the operational burden of inventory management and order fulfillment.

Dropshipping is commonly used by e-commerce businesses to streamline operations, reduce overhead costs, and expand product offerings while focusing on sales and marketing efforts to drive growth.

Inventory Control Methods

Effectively managing inventory is crucial for businesses to ensure smooth operations and maximize profitability. Inventory control methods help organizations maintain accurate records, minimize losses, and optimize stock levels. Let’s explore various inventory control methods in detail:

FIFO (First In, First Out)

FIFO, or First In, First Out, is a common inventory control method based on the principle that the oldest inventory items are sold or used first. In FIFO, inventory items are assumed to be sold or consumed in the order they are acquired or produced.

Key features of FIFO:

- Cost Flow: Under FIFO, the cost of goods sold (COGS) is based on the cost of the oldest inventory items, while ending inventory reflects the cost of the most recently acquired items.

- Inventory Valuation: FIFO results in a more accurate valuation of inventory during periods of inflation since it reflects current market prices.

- Compliance: FIFO is generally accepted accounting principles (GAAP)-compliant and is widely used in industries where product expiration or obsolescence is a concern, such as food and pharmaceuticals.

FIFO is suitable for industries with perishable or rapidly changing inventory, as it ensures that older items are sold before they become obsolete or expired.

LIFO (Last In, First Out)

LIFO, or Last In, First Out, is an inventory control method where the newest inventory items are sold or used first, with the assumption that the most recent costs are matched against revenue.

Key features of LIFO:

- Cost Flow: Under LIFO, the cost of goods sold (COGS) is based on the cost of the most recently acquired or produced inventory items, while ending inventory reflects the cost of the oldest items.

- Tax Benefits: LIFO can result in lower taxable income during periods of inflation since it matches higher current costs against revenue, reducing taxable profits.

- Inventory Valuation: LIFO may not accurately reflect the actual flow of goods and can lead to distorted inventory valuation, especially during periods of inflation.

LIFO is commonly used in industries such as retail and manufacturing, where inventory costs tend to rise over time, and tax considerations outweigh the disadvantages of distorted inventory valuation.

Weighted Average Cost

Weighted Average Cost is an inventory valuation method where the cost of goods sold (COGS) and ending inventory are calculated based on the average cost of all units in inventory.

Key features of Weighted Average Cost:

- Cost Calculation: The weighted average cost is calculated by dividing the total cost of goods available for sale by the total number of units available for sale.

- Simplicity: Weighted Average Cost is straightforward to calculate and easy to understand, making it suitable for small businesses with simple inventory systems.

- Smooths Cost Fluctuations: Weighted Average Cost smooths out cost fluctuations over time, providing a stable cost basis for inventory valuation.

Weighted Average Cost is commonly used in industries with homogeneous or interchangeable inventory items, such as manufacturing and distribution, where individual item costs are not significant.

Specific Identification

Specific Identification is an inventory valuation method where the actual cost of each individual inventory item is tracked and used for inventory valuation.

Key features of Specific Identification:

- Precision: Specific Identification provides the most accurate valuation of inventory since it tracks the actual cost of each item.

- Complexity: Specific Identification can be complex and labor-intensive, requiring detailed record-keeping and tracking of individual inventory items.

- Suitability: Specific Identification is commonly used for high-value or unique items, such as luxury goods, artwork, or customized products, where each item has a distinct cost and value.

Specific Identification ensures accurate inventory valuation for items with significant cost variations or where individual item costs are material to the overall valuation.

Batch Tracking

Batch Tracking is a method of inventory control that involves tracking and managing inventory in discrete batches or lots.

Key features of Batch Tracking:

- Traceability: Batch Tracking enables businesses to trace the movement of inventory from production or procurement through distribution and sale.

- Quality Control: Batch Tracking allows businesses to monitor the quality and characteristics of inventory items within specific batches, facilitating recalls or quality control measures if necessary.

- Regulatory Compliance: Batch Tracking is essential for industries with regulatory requirements for product traceability and recalls, such as pharmaceuticals and food production.

Batch Tracking is commonly used in industries where products are manufactured or processed in batches, such as pharmaceuticals, chemicals, and food processing.

Serialized Inventory

Serialized Inventory is an inventory control method where each individual inventory item is assigned a unique serial number or identifier.

Key features of Serialized Inventory:

- Individual Tracking: Serialized Inventory allows businesses to track and trace each individual inventory item throughout its lifecycle, from production or procurement to sale and beyond.

- Asset Management: Serialized Inventory facilitates asset management and maintenance tracking by associating specific inventory items with maintenance records, warranties, or service history.

- Security: Serialized Inventory enhances security by deterring theft and unauthorized use through individual item identification and tracking.

Serialized Inventory is commonly used for high-value or high-risk items, such as electronics, medical devices, and machinery, where individual item tracking is essential for accountability and security.

Inventory Management Software Solutions

Managing inventory manually can be time-consuming and prone to errors. Inventory management software solutions offer automation and efficiency, enabling businesses to streamline their inventory processes and make data-driven decisions. Let’s delve into the world of inventory management software:

What is Inventory Management Software?

Inventory management software is a digital solution designed to help businesses track, manage, and control their inventory more effectively. These software systems provide a centralized platform for managing all aspects of inventory, including procurement, storage, tracking, and replenishment.

Key features of inventory management software include:

- Inventory Tracking: Enables businesses to track inventory levels in real-time, across multiple locations or warehouses.

- Order Management: Facilitates order processing, including order entry, fulfillment, and invoicing.

- Supplier Management: Allows businesses to manage relationships with suppliers, track vendor performance, and streamline procurement processes.

- Reporting and Analytics: Provides reporting and analytics tools to analyze inventory data, monitor key performance indicators (KPIs), and identify trends or patterns.

- Integration: Integrates with other business systems such as accounting software, e-commerce platforms, and enterprise resource planning (ERP) systems for seamless data exchange and process automation.

Inventory management software solutions come in various forms, including on-premise software, cloud-based solutions, and Software-as-a-Service (SaaS) platforms, offering scalability and flexibility to meet the needs of businesses of all sizes and industries.

Features and Benefits

Inventory management software offers a wide range of features and benefits that can help businesses improve efficiency, reduce costs, and enhance customer satisfaction:

- Real-time Visibility: Provides real-time visibility into inventory levels, locations, and movements, enabling businesses to make informed decisions and respond quickly to changes in demand or supply.

- Optimized Inventory Levels: Helps businesses maintain optimal inventory levels by automating reorder points, safety stock calculations, and demand forecasting.

- Cost Savings: Reduces inventory holding costs, stockouts, and overstocking by optimizing inventory levels and streamlining procurement processes.

- Improved Accuracy: Minimizes errors and inaccuracies associated with manual inventory management through automation and barcode scanning.

- Enhanced Customer Service: Ensures product availability and timely order fulfillment, leading to improved customer satisfaction and loyalty.

- Streamlined Operations: Automates inventory-related tasks such as receiving, picking, packing, and shipping, reducing manual labor and improving operational efficiency.

- Compliance: Helps businesses comply with regulatory requirements such as lot tracking, serialization, and expiry date management in industries such as pharmaceuticals and food production.

Overall, inventory management software solutions enable businesses to optimize their inventory processes, reduce costs, and improve customer service, ultimately driving growth and profitability.

Popular Inventory Management Software Options

There is a wide range of inventory management software options available in the market, catering to businesses of all sizes and industries. Some popular inventory management software solutions include:

- NetSuite: A cloud-based ERP system that offers comprehensive inventory management features along with financial management, order management, and supply chain capabilities.

- QuickBooks Commerce (formerly TradeGecko): A cloud-based inventory management platform designed for small to medium-sized businesses, offering features such as inventory tracking, order management, and multi-channel sales integration.

- Zoho Inventory: A cloud-based inventory management software solution that provides inventory tracking, order management, and warehouse management features for small to medium-sized businesses.

- Fishbowl Inventory: An inventory management solution designed to integrate with QuickBooks, offering features such as inventory tracking, order management, and manufacturing capabilities for small to medium-sized businesses.

These are just a few examples of popular inventory management software options available in the market. When choosing an inventory management software solution, businesses should consider factors such as their industry-specific requirements, budget, scalability, and integration capabilities to find the best fit for their needs.

Inventory Management Best Practices

Effective inventory management is essential for the success of any business. By following best practices, businesses can optimize their inventory processes, minimize costs, and improve customer satisfaction. Here are some key inventory management best practices:

- Accurate Forecasting: Use historical sales data, market trends, and other factors to forecast demand accurately. By predicting future demand, businesses can ensure they have the right amount of inventory on hand to meet customer needs without overstocking.

- Regular Inventory Audits: Conduct regular audits to verify inventory accuracy and identify discrepancies. Regular audits help prevent stockouts, reduce shrinkage, and ensure that inventory records align with physical stock levels.

- Optimized Reorder Points: Set optimal reorder points based on lead times, demand variability, and safety stock requirements. By establishing reorder points, businesses can automate replenishment processes and maintain optimal inventory levels.

- Supplier Relationships: Build strong relationships with suppliers to ensure timely delivery, negotiate favorable terms, and mitigate supply chain risks. Good supplier relationships are crucial for managing inventory costs, lead times, and product quality.

- Inventory Segmentation: Segment inventory based on factors such as value, demand variability, and turnover rates. By categorizing inventory items, businesses can apply different management strategies and prioritize resources effectively.

- Technology Adoption: Embrace inventory management software, barcode scanners, RFID technology, and other tools to streamline processes, improve accuracy, and enhance visibility into inventory operations.

- Cross-Functional Collaboration: Foster collaboration between departments such as sales, operations, finance, and procurement to align inventory management goals with overall business objectives. Cross-functional collaboration ensures that inventory decisions are aligned with broader strategic initiatives.

- Continuous Improvement: Continuously monitor inventory performance, analyze key metrics, and identify opportunities for improvement. By adopting a culture of continuous improvement, businesses can optimize inventory processes, reduce costs, and enhance efficiency over time.

Implementing these best practices can help businesses achieve efficient inventory management, improve operational performance, and gain a competitive advantage in the market.

Inventory Management Challenges

While effective inventory management offers numerous benefits, businesses also face several challenges in managing their inventory effectively. Here are some common challenges in inventory management:

- Demand Variability: Fluctuations in customer demand can lead to stockouts or excess inventory. Managing demand variability requires accurate forecasting, safety stock planning, and agile inventory management processes.

- Supply Chain Disruptions: Disruptions such as supplier delays, transportation issues, natural disasters, or geopolitical events can disrupt the supply chain and impact inventory availability. Mitigating supply chain risks requires building robust supplier relationships, diversifying sourcing, and implementing contingency plans.

- Inventory Obsolescence: Products can become obsolete due to changes in consumer preferences, technology advancements, or regulatory requirements. Managing inventory obsolescence requires proactive product lifecycle management, inventory liquidation strategies, and product diversification.

- Stockouts and Overstocking: Balancing inventory levels to avoid stockouts while minimizing overstocking is a constant challenge for businesses. Stockouts can lead to lost sales and dissatisfied customers, while overstocking ties up capital and increases holding costs.

- Manual Processes and Errors: Relying on manual inventory management processes increases the risk of errors, inaccuracies, and inefficiencies. Transitioning to automated inventory management systems and leveraging technology can help reduce errors and improve efficiency.

- Data Management and Visibility: Limited visibility into inventory operations and data silos can hinder decision-making and lead to suboptimal inventory management. Investing in inventory management software and data analytics tools can provide real-time visibility and actionable insights into inventory performance.

- Cost Pressures: Rising inventory carrying costs, including storage, insurance, and obsolescence, can put pressure on profitability. Optimizing inventory levels, streamlining processes, and negotiating favorable supplier terms can help mitigate cost pressures.

- Regulatory Compliance: Compliance with regulatory requirements such as product labeling, traceability, and safety standards adds complexity to inventory management. Ensuring compliance requires implementing robust inventory tracking systems and staying abreast of regulatory changes.

Addressing these challenges requires a proactive approach, strategic planning, and leveraging technology and best practices to optimize inventory management processes. By overcoming these challenges, businesses can enhance operational efficiency, reduce costs, and deliver better customer experiences.

Conclusion

Effective inventory management is crucial for the success of any business, big or small. By implementing best practices, leveraging technology, and staying proactive, businesses can optimize their inventory processes, minimize costs, and enhance customer satisfaction. From accurately forecasting demand to maintaining optimal stock levels and embracing innovative inventory management software solutions, businesses have a range of tools and strategies at their disposal to streamline operations and drive growth.

Remember, inventory management is not a one-time task but an ongoing process that requires continuous monitoring, evaluation, and adaptation to changing market conditions. By staying informed, staying organized, and staying committed to excellence, businesses can navigate the complexities of inventory management with confidence and achieve sustainable success in today’s competitive marketplace. So, whether you’re a seasoned entrepreneur or just starting out, mastering the art of inventory management is a journey worth taking for the long-term health and prosperity of your business.

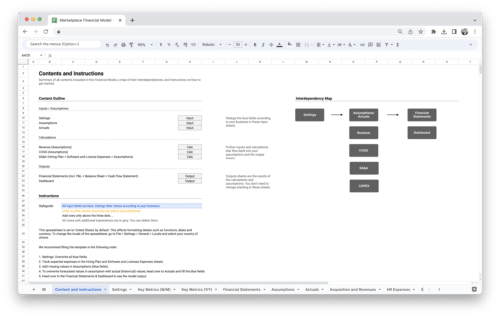

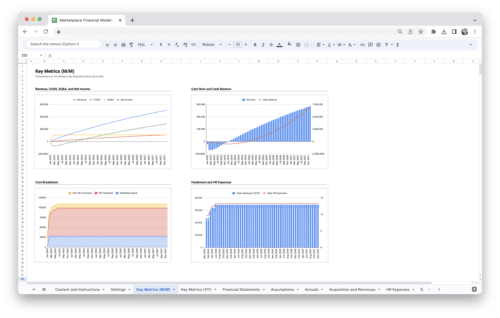

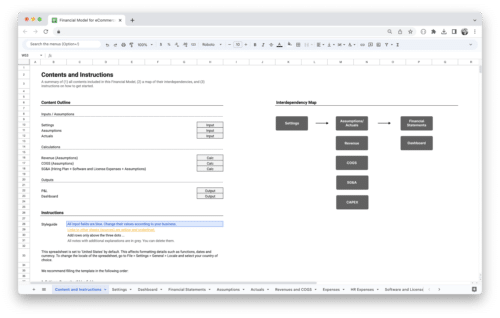

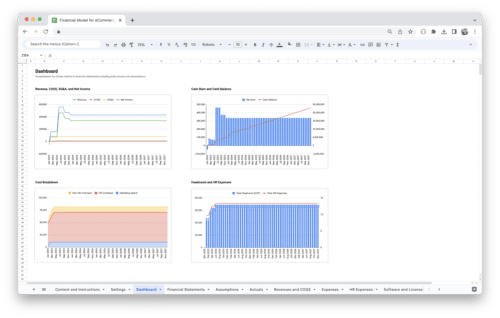

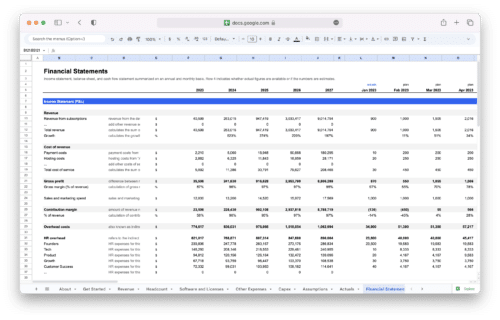

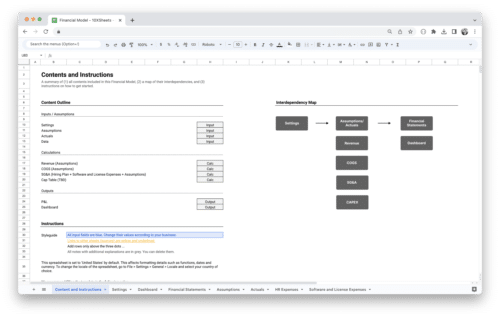

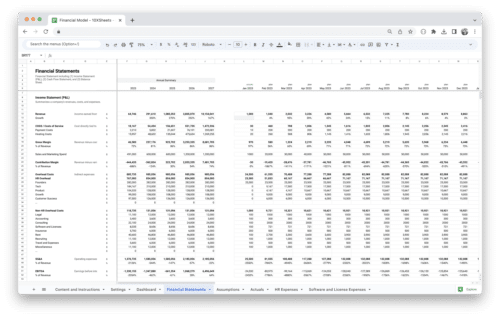

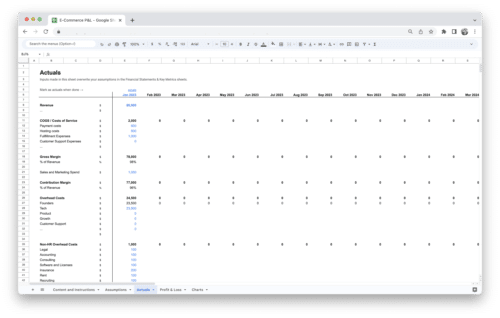

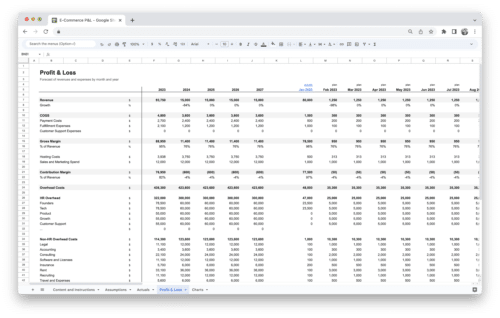

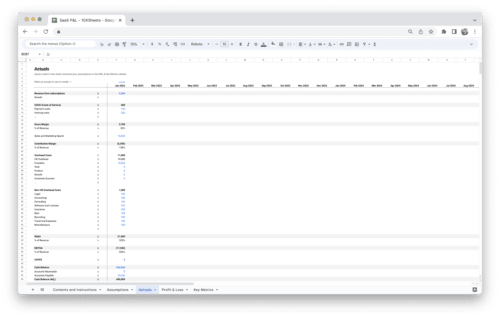

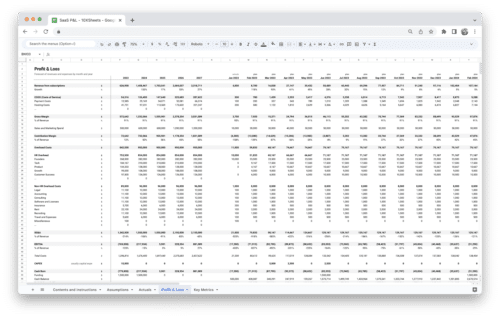

Get Started With a Prebuilt Template!

Looking to streamline your business financial modeling process with a prebuilt customizable template? Say goodbye to the hassle of building a financial model from scratch and get started right away with one of our premium templates.

- Save time with no need to create a financial model from scratch.

- Reduce errors with prebuilt formulas and calculations.

- Customize to your needs by adding/deleting sections and adjusting formulas.

- Automatically calculate key metrics for valuable insights.

- Make informed decisions about your strategy and goals with a clear picture of your business performance and financial health.